Conversions and modifications

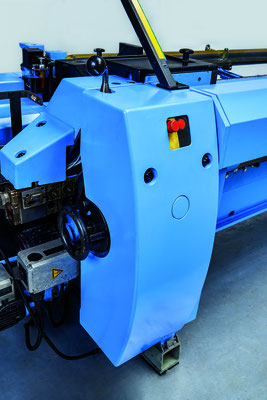

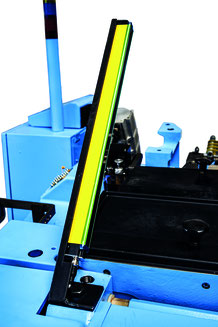

Safety Light Barrier

- active personal protection

- reacts before the moving element can be touched

- simple handling

- rugged construction

- constructed according to the current CE-machine building regulations

- upgradable for the machine types P7100 to P7250 (additional types on request)

PosiLeno (Groz-Beckert)

- upgrade kit to weave with PosiLeno System from Groz-Beckert to weave up and down leno

- available for all sizes and types of projectile machines

- easy handling

- installation on-site in your factory

- machine can work with maximum speed (rpm) also for Leno fabrics

- lower spare parts consumption

- higher fabric quality

- exclusively available at IQ-SPS

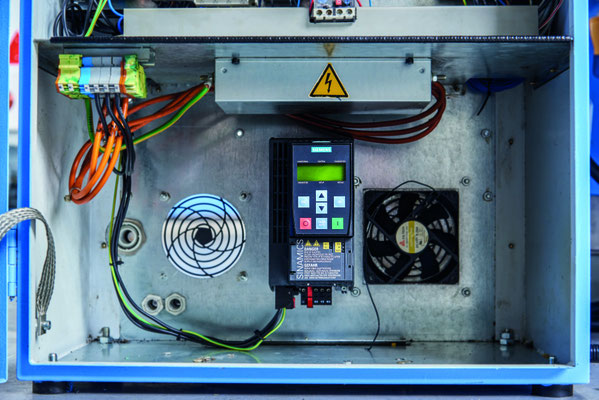

Control Cabinet

- more spacious, more user-friendly

- all controller modules in one place

- installed at weft insertion side

- shorter peripheral cables and thus reduction of possible interfering signals

- shorter walking distances for operation of control cabinet

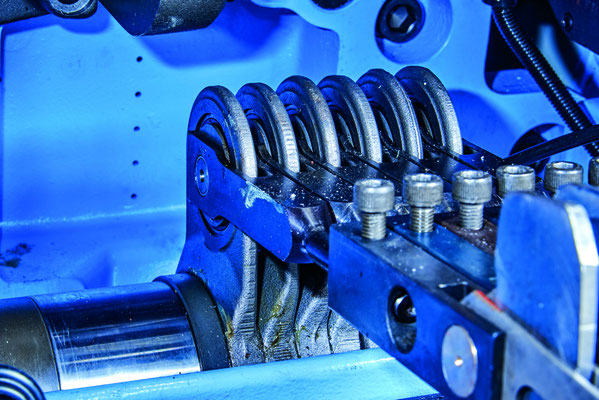

Take-up

- especially designed for heavy and heaviest fabrics

- can be retrofitted to virtually every weaving machine.

- enormous robustness, compact design

- driven first roller.

- extra short fabric support table: reduction of shifting of the weft yarn

- support rollers prevent the bending of the driven rollers

- significant reduction of the so-called recoil of the fell at the beat-up

- special additional frames: existing frames are not subjected to additional loads.

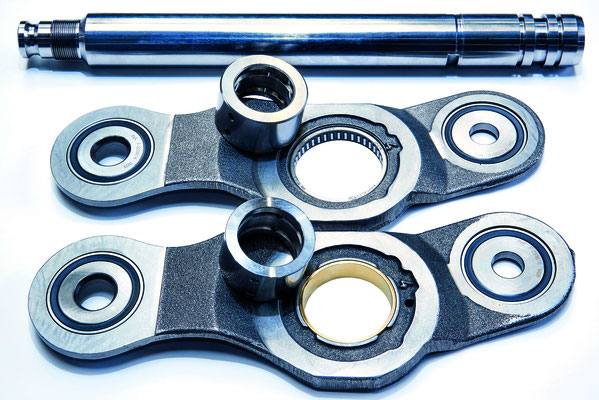

Electronic Let Off Device

- motor with 200N maximum torque

- high torque gear

- 50.000 N axial force

- completely new design

- easy adjustment

With this warp reduction system you can achieve warp pull forces which by far exceed the standard.

Warp Tension Gauge

- optimal warp tension control

- reproducible adjustment of warp tension

- from 2.000 N up to 5.000 N

- easy handling

Lubrication

Further Conversions

- Conversion of single-colour machines to two or even four colours

- Warp beam extensions (e.g. from 940mm to 1016mm - practicable up to 1100mm)

- Conversion from D1 to D12 or D2 on projectile weaving looms (bigger projectile gripper D1 2,2 x 4 D12 3,8 x 5 and D2 4 x 5 or 4 x 6)

- Mounting of whip rollers and deflecting rollers or warp tensioner devices

- Equipment with accessories such as cleaning devices, spool frames or accumulator frames